Radiant Heating System 6

| Some

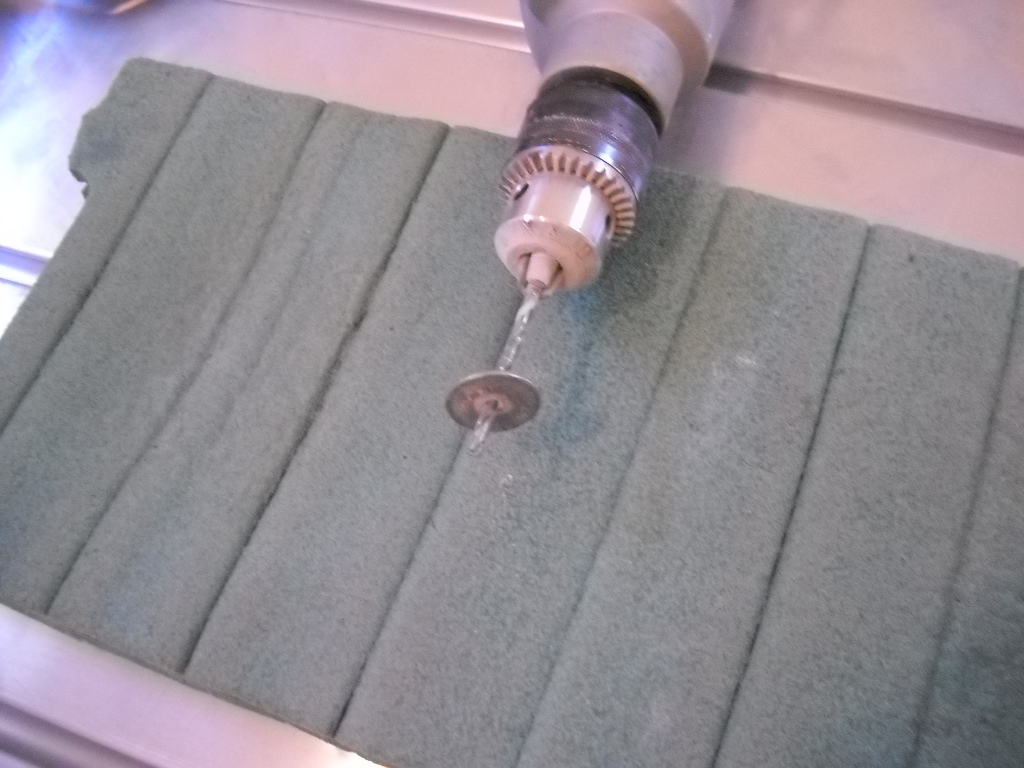

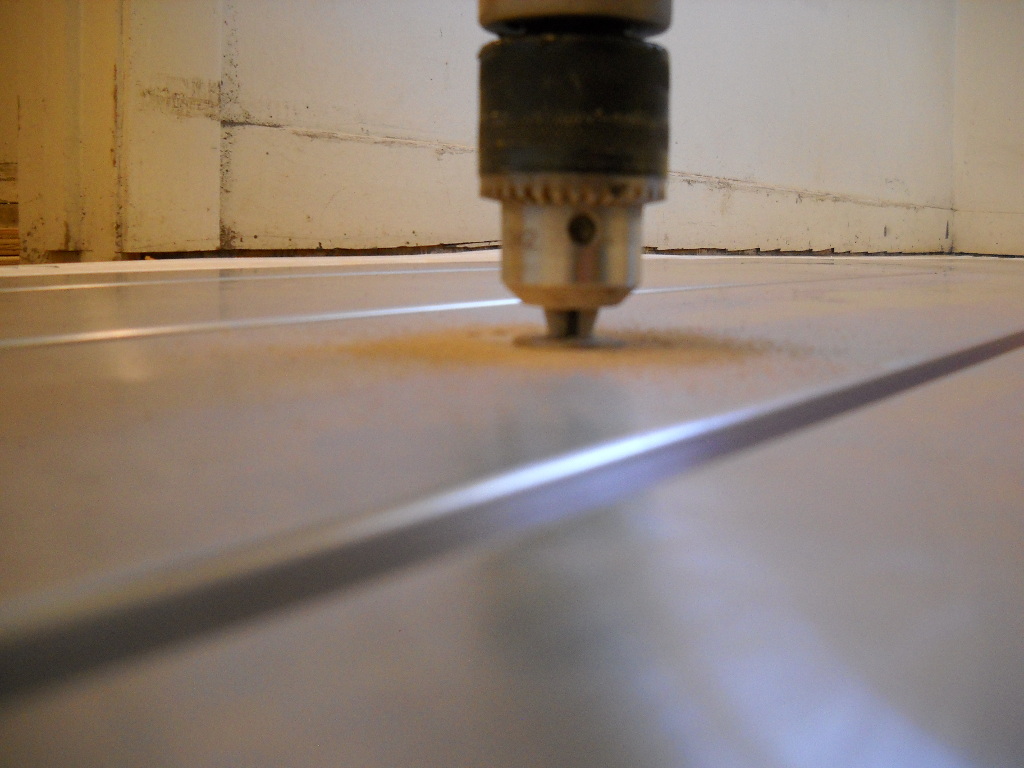

of the tools used for the Roth panel installation. First, a hammer

drill for the TapCon screws. By putting a washer around the bit, I was

able to prevent the chuck from damaging the aluminum plate. |

|

|

|

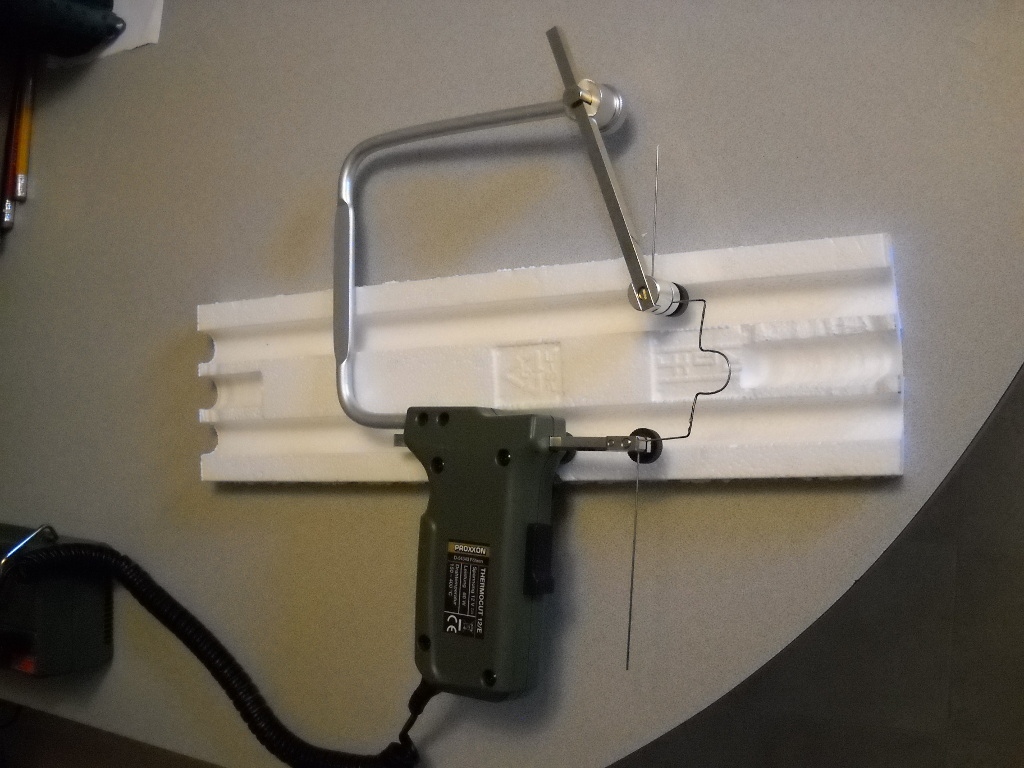

| A

hot-wire cutter to make channels in the styrofoam to route the tubing.

This tool was a huge time saver. I tried using a utility knife at

first, but that just made a mess. |

|

|

| For

channels in plywood nailing strips and thresholds, I used a radial arm

saw to cut part way through the plywood. For curves, I would cut the

outside of the curve with a jig saw, then use the radial arm saw to

make the channel. |

|

|

| The hallway had some of the more complicated runs since this was the route back to the manifold. |

|

|

| After the tubing is installed in

the Roth panels, the panels are covered with 1/4" luan. The luan is

held down with Tap-Con screws, just like the Roth panels. You'll want

to take a lot of measurements as to where the the tubing is located

before you put down the luan. You do not want to puncture the PEX

tubing. |

|

| After the luan is down, you can

install the carpet tack strips around the perimeter. For padding, you

need to use something with a low R-value. Regular carpet padding with

block the heat. I used Tred-MOR 2500 1/4" slab rubber padding seen in a

roll here. This stuff is very heavy. In fact you do not need to fasten

it down...it will stay wherever you put it. |

|

| The

Buderus indirect water heater failed after about 7 years. The heating

coil sprung a leak into the water tank. Apparently, Buderus indirects

are notorious for doing this, so I had it replaced with a Crown

stainless steel 40 gallon indirect. The Buderus boiler has been running

great, however I did have to switch maintenance contractors to find someone who

really knows Buderus. I had five different companies come out with a

no-heat issue two winters ago. The last guy, who is the one that fixed

it, was aware of a service bulletin on the Riello burner that specified

a higher pressure setting (like 200 psi vs. 160 psi). Once that was

done, we were working perfect again. |

|

| Still to be done on this project are two bathrooms that will be heated with Runtal towel warmers. I will update this site as the project progresses. |

<- Previous Home